X-Ray Generators by Golden Engineering

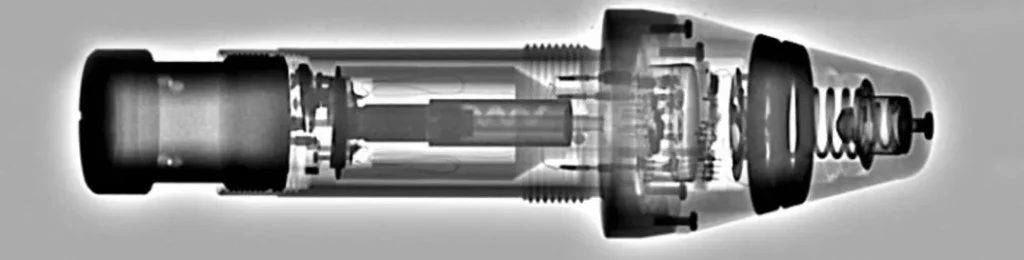

Explore our range of Golden Engineering X-Ray Generators – the epitome of robustness, dependability, lightweight design, and safety. Trusted by military and law enforcement agencies, these pulsed X-ray generators redefine portable radiography for security and light industrial applications.

Golden Engineering stands out in the industry for its commitment to excellence. The XR150, XR200, XRS3, and the robust XRS4 represent the pinnacle of portable X-ray technology. These generators boast superior penetrating ability, making them more efficient and effective than alternative technologies. Despite their power, they are smaller and lighter, providing unparalleled convenience without compromising performance.

Safety is paramount, and Golden Engineering X-ray generators excel in this aspect. These systems are designed with zero radioactive materials, ensuring a secure working environment. They feature minimal leakage and remarkably short exposure times, making them one of the safest solutions available in the market.

An innovative approach sets Golden Engineering apart – they are the only manufacturer utilizing commercially available battery packs as a power supply for their portable X-ray generators. This design ensures accessibility and ease of replacement, allowing for seamless operation in almost any country globally.

Choose HTSL for a comprehensive range of Golden Engineering X-ray generators that redefine the standards of portability, safety, and efficiency.

Non Destructive Testing

X-rays are indispensable in Non-Destructive Testing (NDT) applications across a spectrum of industries, including Electronics, Petrochemicals, and general manufacturing.

NDT is a critical process involving the examination of objects without compromising their future utility. Among the various technologies employed in NDT, X-rays stand out as a primary tool. NDT entities encompass a wide range, from Petrochemical, manufacturing, and construction companies to Universities and the Military. NDT settings can vary from comfortable laboratory environments to extreme conditions.

The applications of NDT are diverse, with some requiring multiple X-ray images per hour, while others need only a few X-ray images per month. The table below succinctly outlines the key attributes crucial in the NDT market.

| NDT Application | Golden X-ray Benefits | |

| Convenience | Minimal disruption to normal on-going operations | Exclusion zone allow for reduced interruptions in normal operations. The X-ray generator’s single package design and no warm up required saves time during set up. |

| Portability | Applications often require X-ray be transported and used in remote locations with no access to power | Battery powered and light weight, the X-ray generators can be easily transported and operated in remote settings. |

| Safety | May require inspections within a relatively close proximity to personnel | Golden Engineering Pulsed X-ray generators contain no radioactive material. Minimal leakage to side and rear of the machine and minimal exposure time reduces standoff distance around the machine and reduces the possibility of accidental exposure. |

| Durability | Products often exposed to harsh environmental conditions Some applications require continual use | Rugged design can be used in a variety of environmental conditions and temperatures between -10 to 120 degrees F. Light duty technology is not intended for continual use. Applications that require continual use will require multiple generators and some applications are not viable for light duty X-ray generators. |

| Image Quality | Wide variety of image quality required | A 3 mm source size means X-ray may not be suited for some high resolution applications. |